Proving the Case for Net Zero Waste Collection with Serco

By George Hobbs, Consultant and Data Lead

I gave a presentation yesterday with George Roach, Performance and Compliance Director at public services provider Serco, about the results of our 8-week pilot of electric refuse collection vehicles – eRCVs. We were at the Resource & Waste Management Conference at the NEC, alongside Refuse Vehicle Solutions Ltd (RVS) who provided the electric vehicles for the pilot. It was a great session because we had a great story to tell –

- The two eRCVs completed their collection rounds in two Hampshire districts.

- The drivers preferred driving the smooth & quiet eRCVs to the usual diesel vehicles.

- The carbon emissions saving over 8 weeks was equal to two cars for an entire year.

- The business case stacked up.

Maximum sustainability – vehicle conversion diesel to electric

The eRCVs were not brand new vehicles. RVS converted and repowered diesel vehicles into as-new electric vehicles, adding to the carbon emission savings.

Vehicle conversion reaps benefits in terms of a second life for vehicles, reduced scrappage and saving manufacturing emissions in the production of new models. It’s the very definition of sustainability.

Serco wanted real-world data to inform its fleet electrification plans

As a key supplier to local councils, Serco has a responsibility to support the councils’ carbon emission goals. The councils participating in the eRCV pilot were among the 300 UK councils that have declared a climate emergency. And with refuse and recycling collection contributing a large proportion of a council’s emissions, switching to electric vehicles would be a major win for them.

Serco is already planning its waste fleet electrification, installing grid connections and underground cable ducts for charger installation at depots. They’re also using HVO as an interim decarbonisation method in some cases.

VEV had completed a feasibility assessment for one depot, using vehicle telematics and other operational data. Serco wanted to add real-world data to the modelling to further inform its roll-out plans for electric vehicles. The pilot aimed to demonstrate:

- Emissions savings

- Operational feasibility

- Business case to electrify RCV fleets

Key facts and stats about the eRCV pilot

We modelled the routes to identify which were ready for electric vehicles (EV) and would be a fit for the pilot based on distance, tonnage and bin lifts.

We installed one AC charger at each site in charging bays and selected the 22kW Autel Maxicharger for its high durability, reliability and easy maintenance.

The pilot ran for 8 weeks at 2 depots serving 3 councils in Hampshire with 2 repowered electric waste collection vehicles.

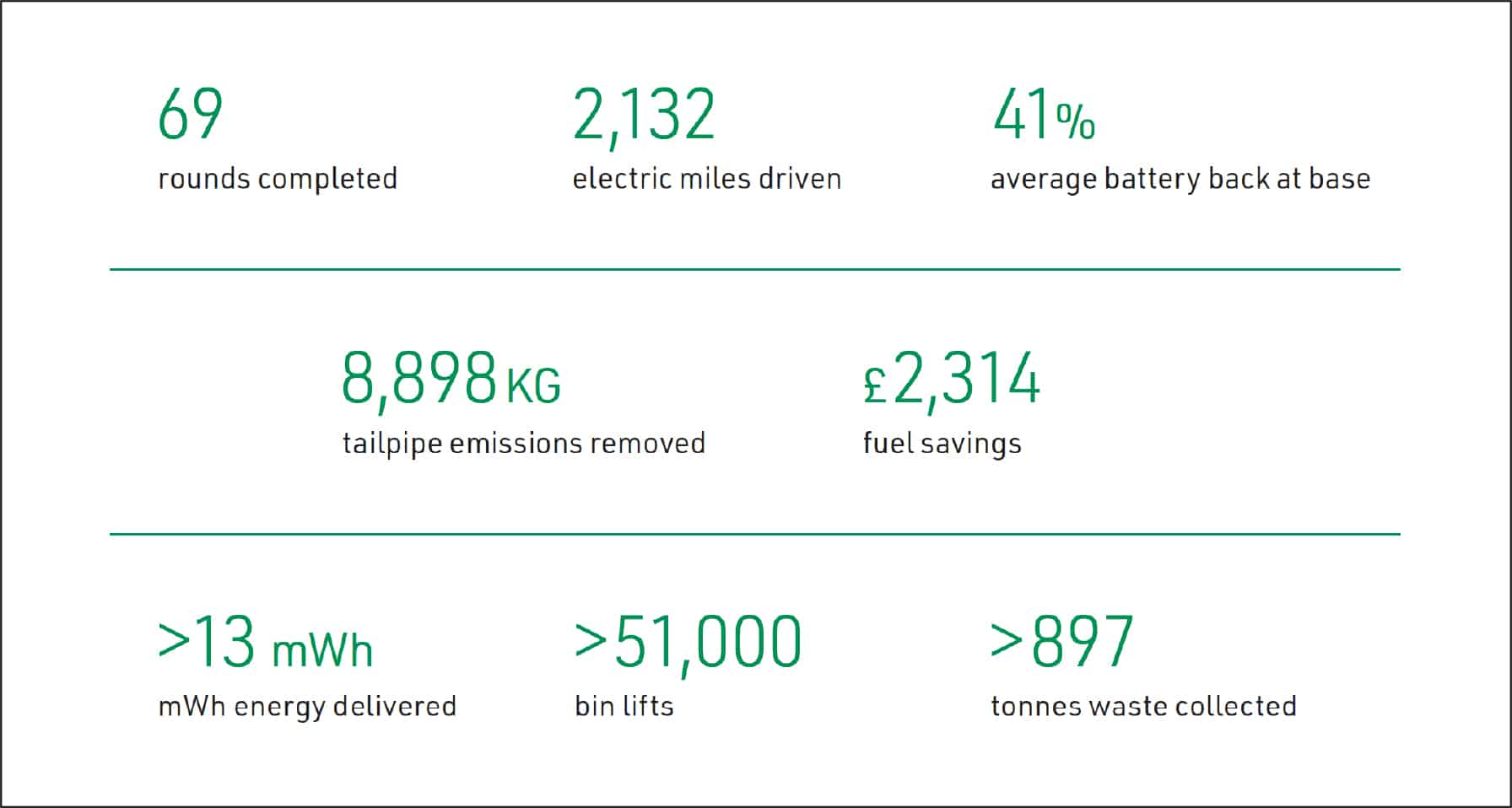

These were the headline numbers

Environmental impact – serving local council decarbonisation goals

The carbon savings of 8,898kg were equivalent to removing two cars from the road for an entire year. This is a major win for councils.

The transition to EVs will be a major contributor to the emissions goals of the councils, both of which have declared climate emergencies.

- Council 1 aims to be a net-zero borough by 2030, addressing the 38% of operational emissions from the waste fleet.

- Council 2 aims to be carbon neutral by 2030, addressing the 17% of total emissions from waste.

Not measured during the trial but equally important are particulate emissions, which have harmful health effects, and noise pollution. Imagine the positive impact in our communities when our streets are served by quieter, cleaner vehicles.

Vehicle performance and efficiency

Efficiency varied as we changed rounds and drivers but trended up in the 8 weeks.

Vehicle adjustments were made to reduce auxiliary power consumption. And drivers learned how to drive an EV e.g. feathering the accelerator to account for the torque.

- Council 1 efficiency varied between 0.13 – 0.28 miles/kWh – the difference between completing a 37- or a 78-mile trip.

- Council 2 efficiency varied between 0.10 – 0.22 miles/kWh – the difference between completing a 28- or a 60-mile trip.

Range is not just a factor of battery size and distance – route planning needs to account for auxiliary power use.

Power – develop a robust strategy up front

eRCVs consume substantial amounts of power and it is crucial to complete a grid and solar power assessment at the planning stage of any fleet electrification.

Charging schedules are a key element in the operations of an EV fleet. In the pilot the average charging window was 16 hours, the average charging session took 160-210kWh and the average charge SOC (state of charge) was 50-65%. Charging at 22kW, this required only around half of the charging window.

The vehicles returned to base with an average 41% battery charge, which negated range anxiety during the pilot. The available charge also offered operational flexibility to adjust charging windows and/or complete unplanned additional rounds.

Duty cycles of eRCVs returning early afternoon make waste collection depots ideal for solar power generation. Using sunlight hours to charge from solar reduces costs and the demand from the grid.

AC versus DC Charging – moving to DC charging opens opportunities for added resiliency and flexibility, e.g. for emergency charging sessions and switching to cheaper energy tariff times.

Driver feedback – attitudes to EVs became more positive through the trial

The feedback from the drivers highlighted the importance of real-world use of EVs to overcome scepticism from drivers and operational teams. Changes to working practices can become a blocker if the workforce is not properly consulted, trained and listened to.

Some of the comments we received:

“I like how quiet it is, I can hear the crew working behind me much easier, it feels much safer”

“A very enjoyable experience”

“Can I keep it?”

Early and frequent communication with drivers and operations teams is critical to help identify, mitigate and resolve any challenges and we tracked a significant change in attitudes as the pilot progressed.

Driver education is also crucial to maximise the efficiency and range of the EVs in the fleet, which is obviously crucial for cost management.

The pilot showed that eRCVs will deliver net zero emissions for net zero cost increase

No diesel to electric fleet transition will happen unless the business case works. This was obviously a key goal of conducting the pilot and it demonstrated parity in TCO (total cost of ownership) with diesel RCVs.

With further optimisation and conservative modelling across service, maintenance & repair strategy, vehicle technology advances and fuel regulatory policy, VEV found a further 14% saving is possible.

This excludes fuel price increases and government subsidies that can make the TCO even more beneficial.

Embrace the change to achieve net zero emissions for net zero cost increase

With open minds about adjusting operational patterns to optimise the efficiency of an EV fleet, tangible benefits can be achieved. It’s the marginal gains that collectively make the difference – in charging scheduling, vehicle selection and battery weights, use of solar power and battery storage, driver training, energy tariffs and charging infrastructure decisions.

On a personal note, I can’t express how proud I am of what we achieved on this project. Working with Serco and RVS on this transformative project has been an absolute pleasure for the VEV team.

If you’re curious to learn more about building the case for electrifying refuse collection vehicles, please contact me.

Download the full report on the eRCV Pilot, here.